7 Miles of Pipe – On Time, On Budget

The Lake Charles Chemical Complex (LCCC) consists of a world-scale 1.5 million ton per year ethane cracker, and six downstream chemical units adjacent to Sasol’s existing chemical operations.

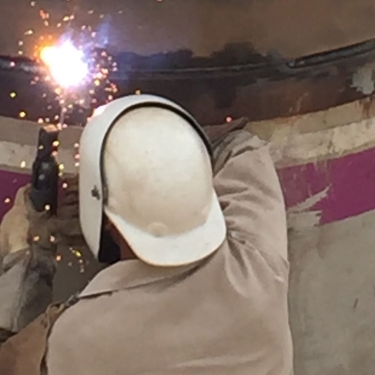

For this major chemical project, BCI worked under Cajun as a subcontractor to Fluor Technip, a joint venture serving as the primary engineering, procurement and construction management contractor. BCI provided supervisory and welding resources for the installation of over seven miles of process piping to major units, including a cooling tower.

As of April 2017, the project deliverables were on-time, in-specification and well within budget, with all Sasol QA/QC specifications met or exceeded. In fact, the value-added contribution by that point was already $4.5 MM to date, with an additional $3 MM projected for 2017. In an assessment performed by Fluor Technip to improve overall reliability of the project, BCI was recognized for having a weld defect rate of 0.04 percent.